|

|

|

|

#1

|

||||

|

||||

|

Does tire size affect frame durability?

I got asked this by my brother during a ride and, as an opinionated know-it-all, I was quite embarrassed when I had to tell him I wasn't really sure and hadn't read or seen much about it.

Basically, if you have a frame that will accept 700cx38 tires but only ever ride it with 700cx25 tires will the larger tires reduce fatigue loads on the frame/fork? Assume both tires are at 15% sag, rider weight the same, riding surface and style the same, etc. etc. etc. Let's say our hypothetical frame was designed around the rider's weight and for 700cx38 tires as the max for road and light trail riding. We were talking about steel but speculate AL or CF if you prefer - does the specific properties of those materials change the answer? Standard diameter tubing or OS change the answer? |

|

#2

|

|||

|

|||

|

I doubt anyone has done any actual testing on the matter. However it's a pretty good assumption that with more air volume there's less vibration and load going into the frame and a reasonable result is that durability would increase. By how much, who knows. Worthy of bull****ting about while riding bikes I suppose.

|

|

#3

|

|||

|

|||

|

I know this is a sample of 1, but I don't think I've ever broken a frame due to vibration. I broke a $4it to when I was racing, (discounting crashed frames), but none since, frequently using the same size tires. I'm guessing it's due to overstressing the tubing/joint beyond it's limit until failure. If it's failure is due to vibration, I would speculate that the material is underspec'd for the load.

Paging Mark McM |

|

#4

|

|||

|

|||

|

Quote:

Remember that steel (and titanium) are favored for bicycle frames because of their relatively high "fatigue limit": if the material is subjected to loads below the fatigue limit, it can be subjected to an infinite number of load cycles and *never* fail. |

|

#5

|

|||

|

|||

|

Under normal road conditions, frames usually fail due to crashes, corrosion, or manufacturing defect. I doubt the tires would make a difference.

But I'd you're talking something like pros riding Paris Roubaix, for sure I think wider tires would prevent failures... But frames aren't often the first thing to go--the wheels are usually the first thing to go after the tire, and wider tires definitely protect the rim better.

__________________

Instagram - DannAdore Bicycles |

|

#6

|

|||

|

|||

|

Short answer is no, tire size will not affect loads into the frame or frame durability.

The loads come the rider up top and the road down below. The tires between are just part of the load path, and changes tires from say 38mm to 25mm won't change that...unless 38mm means the rider now rides trails or some such. |

|

#7

|

||||

|

||||

|

Quote:

Pretty simple concept really, more air volume adds suspension effect and reduces shock loading.

__________________

http://less-than-epic.blogspot.com/ |

|

#8

|

|||

|

|||

|

You could even argue the torque on the fork and frame is greater with leverage increasing by 10 mm.

Apart from carbon MTB's and rusty steel. Who is breaking frames these days? |

|

#9

|

|||

|

|||

|

Anything that changes the magnitude or frequency of cyclic loads will have an effect on fatigue life (all else being equal). If the fatter tires at a lower pressure results in lower shock loading, then it will decrease the fatigue rate. Enough to matter? Hard to say. It could even have a reverse effect, if the fatter tires encouraged riding on rougher surfaces.

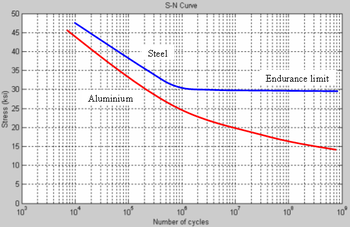

As long as a frame is made with an adequate fatigue life, this is probably just an academic question. As far as a "fatigue limit": This is a theoretical concept, and not a true reality. Eventually any structure will fail from fatigue. For materials said to have a "fatigue limit" (such as steel or titanium), what actually happens is that below a certain stress (typically about half the ultimate tensile stress) the fatigue life (cycles to failure) increases dramatically, but it never truly reaches infinity. This is illustrated in this graph from the Wikipedia article on Fatigue Limit:

|

|

#10

|

|||

|

|||

|

Softer tires will inevitably allow and encourage the rider to go faster on the fastest, roughest sections.

And it's on the fastest sections where one's line of sight is farthest out, meaning that hitting bigger unseen pot holes and rocks is likely. It's these biggest impacts which would seem to have the biggest effect on fatigue. I am envisioning two spring/mass vibration modes, one being the rider's mass with the bike being the spring, and the other being the front wheel/tire mass vibrating between two springs, the cantilevered fork and the compressed tire. A skinnier tire, inflated harder to equally protect the rim from worst-case, sharp-edged impacts, would offer less suspension travel and thus a higher spring rate than a fatter/softer tire. But I doubt that riders typically inflate narrower tires to that degree of rim protection. To the degree that the rider's speed is being limited more by fear of crashing or of tire pinching (rather than by the discomfort of vibratory impact magnitude), then perhaps narrower tires would effect a longer frame life. |

|

#11

|

|||

|

|||

|

Also, goes without saying that if your oversized tire saws through the chainstay, durability might be compromised.

|

|

#12

|

|||

|

|||

|

Quote:

I agree with you that fatigue limits are not really very useful. This is especially true with welds. Steel welds do NOT show any fatigue limit behavior (nor do other welded metals), and since almost all metal bikes are welded together, the idea of the fatigue limit is really a waste of time. |

|

|

|